Knowledge of computerized tracking systems is frequently considered advantageous for individuals in this position.Ī bachelor’s degree in mathematics or inventory management is typically required for an inventory manager position. The capability of an inventory manager to apply analytical skills to inventory control is generally regarded as an asset. Typically, success in this position requires an uncanny ability to pay attention to detail and exemplary organizational abilities. If the latter option proves to be more profitable, the manager frequently makes adjustments to her inventory ordering and storage systems to boost revenue. She compares it frequently to the cost of ordering goods on a need-to-know basis. To ensure that the highest profit margins are maintained and that production and sales do not suffer interruptions, an inventory manager typically keeps track of the costs associated with storing slow-moving inventory. Typically, a system for tracking backorders and returns is integrated into the program’s mainframe. She typically maintains a specific inventory level for each part or product in stock and is alerted to reorder when it reaches that level. When inventory is small or when demand for it varies significantly and frequently, the inventory manager typically monitors it manually or via a computerized inventory tracking system. Popular items are inventoried more frequently than slower-moving items, with only a few items inventoried daily. This practice entails counting various components of the inventory to ensure that each component is inventoried at least once during a specified period, typically six months or a year. Certain businesses that deal in large volumes of components and parts conduct cycle counts regularly. Her ability to assess current needs and forecast future requirements is frequently critical to her inventory control effectiveness.ĭepending on the volume of inventory and the nature of the business, an inventory manager may utilize a variety of different methods for stock management.

Typically, the inventory manager is responsible for monitoring inventory levels and placing orders for additional merchandise as needed to meet the needs of her company or its customers. Inventory control efficiency is typically critical to a business’s success. She may work in the public or private sector for a large or small company. Typically, the inventory manager collaborates with other departments and supervises one or more inventory clerks. Inventory may be used internally or may include goods sold or rented to customers. Additionally, because such errors reflect poorly on the company, they can result in negative reviews or erode customer loyalty.Īn inventory manager is in charge of a company’s goods, materials, products, or parts. These errors harm an organization’s profitability, as they waste both money and employee time correcting errors. This ultimately results in out-of-stocks and excess inventory. When businesses place orders manually and do not have a complete picture of their inventory, they cannot forecast inventory requirements accurately. Mis-shipments, in turn, are the result of incorrect selections at the start of the process. When warehouses are not managed properly, mis-picks can occur as a result of disorganized shelves, incorrect paper pick lists, or a cluttered warehouse.

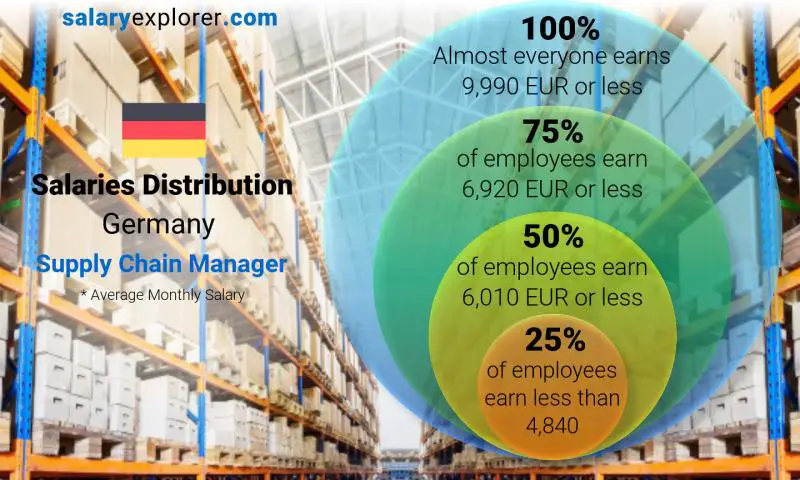

INVENTORY MANAGER SALARY SERIAL

Inventory management entails the collection of a variety of different types of data to keep track of the goods, including the number of goods, the cost of goods, serial numbers, lot numbers, and dates. Wholesale distributors deal in finished products rather than raw materials. In smaller businesses, goods received directly from the manufacturer may be placed in the stock area. While inventory management processes can become more complex in larger organizations, the fundamental process remains the same: goods are received in the warehouse and placed on shelves or in stock areas they are then moved to production facilities where they are transformed into finished goods and then shipped directly to customers. Inventory management is critical for maintaining detailed records of new and returned products as they enter or exit the warehouse or point of sale. Inventory management is a function of supply chain management that entails monitoring the flow of goods from manufacturers to warehouses and finally to the point of sale. Top 20 Inventory Manager Interview Questions and Answers for 2022

0 kommentar(er)

0 kommentar(er)